Injection molding is the heart of automotive industry as more than 90% of the plastic or rubber or glass used in an automotive is moulded in it to acquire final shape & standards required. You just name a plastic part & from as small as fasteners to as big as Inst. Panel, everything is injection molded.

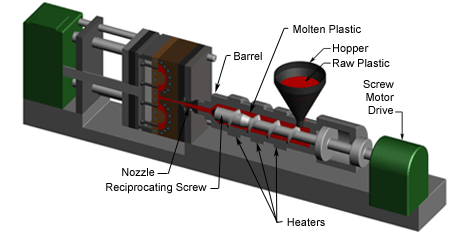

- Granulated or powdered thermoplastic plastic is fed from a hopper into the Injection Moulding machine.

- A hollow steel barrel, containing a rotating screw (Archemidial Screw) , carries the plastic along the barrel to the mold.

- Heaters surround the barrel melt the plastic as it travels along the barrel.

- The screw is forced back as the melted plastic collects at the end of the barrel.

Once enough plastic has collected a hydraulic ram pushes the screw forward injecting the plastic through a nozzle into a mould cavity.

The mould is warmed before injecting and the plastic is injected quickly to prevent it from hardening before the mould is full.

Pressure is maintained for a short time (dwell time) to prevent the material creeping back during setting (hardening). This prevents shrinkage and hollows, therefore giving a better quality product.

Hello, I completely agree with you. Really, Injection Molding system has more demand in the recent market and specially for mold making company. Good descriptive post. Keep it up...

ReplyDelete