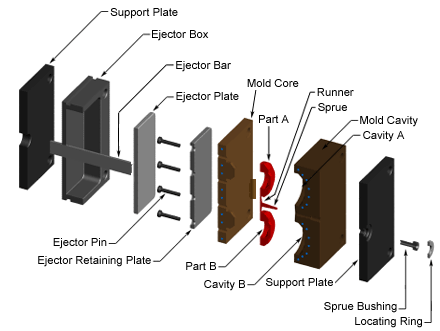

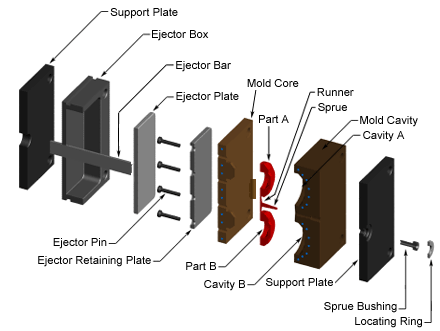

• Molten plastic enters the mold through the sprue . Additional channels, called runners, carry the molten plastic from the sprue to all of the cavities that must be filled.

• At the end of each runner, the molten plastic enters the cavity through a gate which directs the flow.

• The molten plastic that solidifies inside these runners is attached to the part and must be separated after the part has been ejected from the mold

|

Mold - Exploded view

MACHINE SPECIFICATIONS

Injection molding machines are typically characterized by the tonnage of the clamp force they provide.

The required clamp force is determined by the projected area of the parts in the mold and the pressure with which the material is injected (Including thickness).

THUMB RULE : Above 1.5mm thickness/150mm depth = 1 Tons/inch2 Above 1mm thickness/150mm depth = 1.5 to 2.0 Tons/inch2 Above 0.5mm thickness/150mm depth = 2 to 3 Tons/inch2 For 0.5mm thickness/150mm depth = 3 to 4 Tons/inch2

Any further increment in flow length for every inch shall increase the tonnage by 10%

GENERAL FORMULA: PEAK INJ. PRESSURE * TOTAL PROJECTED AREA * F.O.S |

No comments:

Post a Comment